In today’s world, efficiency and cost-saving measures have become essential for businesses across various industries. With the price of metal at an all-time high, it has become imperative to minimize material wastage and maximize the utility of each stock length. A linear cut optimizer can be a game-changer for businesses working with metal, as it enables precise planning and reduces errors when cutting metal lengths. In this blog post, we will delve into the benefits of using a cut optimizer and explore how its implementation can lead to substantial savings.

Understanding the Linear Cut Optimizer

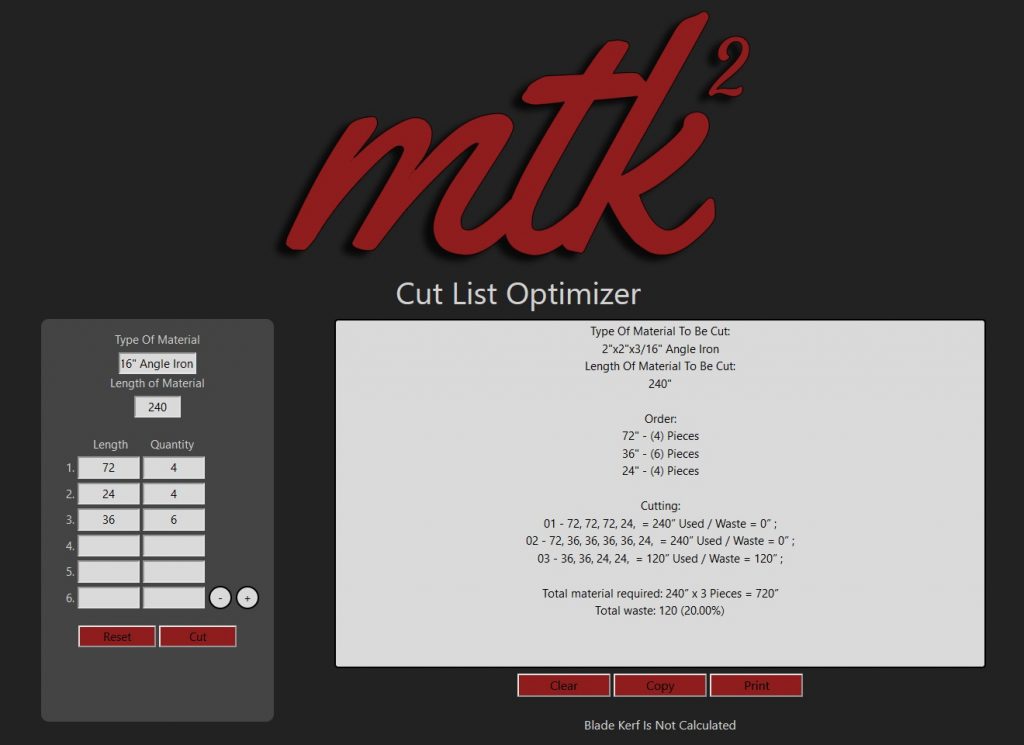

A linear cut optimizer is a software tool designed to optimize the cutting process by efficiently arranging desired cut lengths on a specified length of material. The primary objective is to minimize wastage of material while maximizing the utilization of the available resources. By analyzing the required cuts and nesting patterns, the optimizer can generate the most cost-effective and efficient cutting plan.

The Benefits of Using a Cut Optimizer

- Material Savings and Cost Reduction: The most significant advantage of employing a cut optimizer is its ability to reduce material waste significantly. By intelligently arranging the cutting pieces on the metal stock, the optimizer can minimize off-cuts and remnants, resulting in more efficient material usage. With metal prices soaring, this translates to substantial cost savings over time, making a cut optimizer a valuable investment for any metal-working business.

- Improved Accuracy and Reduced Errors: Manual cutting planning can be a tedious and error-prone task, especially for complex projects. A linear cut optimizer, being driven by precise algorithms, eliminates the risk of human error in the planning process. It ensures that each cut is accurately measured and placed, leading to precise results and a reduction in costly mistakes during the cutting phase. As a result, businesses can enhance their overall productivity and achieve higher quality outputs.

- Time Efficiency: Time is a valuable resource in any production environment. Traditional manual cutting planning can consume a significant amount of time, delaying project completion and reducing throughput. A cut optimizer automates the planning process, swiftly generating optimal cutting plans in a matter of seconds. This enhanced efficiency allows businesses to complete projects faster and take on additional work, increasing their capacity for growth.

- Platform Independence: Java is known for its “write once, run anywhere” philosophy, allowing software to be used on different platforms without modification. A Java-based cut optimizer is highly versatile and can be integrated into various systems, irrespective of the operating system in use. This flexibility enables businesses to seamlessly incorporate the optimizer into their existing processes, regardless of their technological environment.

Conclusion

In the face of soaring metal prices, a linear cut optimizer proves to be an indispensable tool for metal-working businesses. By significantly reducing material waste, improving accuracy, and enhancing overall efficiency, the optimizer enables businesses to make substantial cost savings and deliver high-quality products to their customers. Its adaptability across different platforms through Java makes it even more accessible and valuable for various businesses, regardless of their existing infrastructure.

As we move forward in a highly competitive and resource-constrained world, embracing technology-driven solutions like the linear cut optimizer will undoubtedly be the key to success for businesses in the metalworking industry. Embrace this cutting-edge tool today and unlock the potential for a brighter, more profitable future. Feel free to use MTK Squared’s very own Cut List Optimizer for no cost available at the following link.